Newly released

OrthoGraph© Operational BIM Maintenance

The Key to Continuous Manufacturing Operations

The greatest risk for large factories is unplanned downtime. Even a few hours of downtime can cause hundreds of thousands of euros in losses—in many cases, this number reaches millions. This occurs when equipment stops, production halts, and there is no precise, quickly accessible information about the device or its maintenance history. Restarting production lines is also often problematic: many times it fails at first, which can result in further time loss and scrap production.

Who is OrthoGraph AI Maintenance for?

Manufacturing companies where:

- At least 4 maintenance personnel are employed.

- Downtime costs range from tens to hundreds of thousands of euros per hour, occasionally reaching millions.

- Knowledge resides in the heads of maintenance personnel, and this can be lost due to turnover, retirement, illness, or vacation.

Customer Problems – and Our Solutions

1. Cost of Unplanned Downtime

Problem: Losses amounting to hundreds of thousands of EUR per hour.

Solution:

Imagine noticing an oil stain beneath a machine. Instead of waiting for the right person, the technician can immediately ask the AI: ‘Is this normal for this machine?’ The AI reviews the full documentation and maintenance history, then responds: ‘Generally not typical for this type, but this particular machine has had similar incidents. The standard procedure is as follows…’ Thus, the issue can be addressed immediately—even by someone unfamiliar with the machine. Additionally, integrated Operational BIM provides on-site navigation and direct access to machine documentation. These can include:

- a photo when the machine was last open—helping determine required materials and tools,

- assembly and disassembly videos—since similar machines are common in factories, even a brief video can significantly speed up and ensure safer work,

- a photo of the machine’s data plate aiding in preliminary maintenance planning,

- or an audio recording of the machine’s operational noise, detecting early-stage faults during inspections.

2. Loss of Knowledge Due to Turnover or Retirement

Problem: Maintenance knowledge and factory understanding only exist in employees’ minds.

Solution:

- Complete documentation and event history processed by AI ensures any technician can immediately understand equipment operation, issues, and intervene regardless of prior experience.

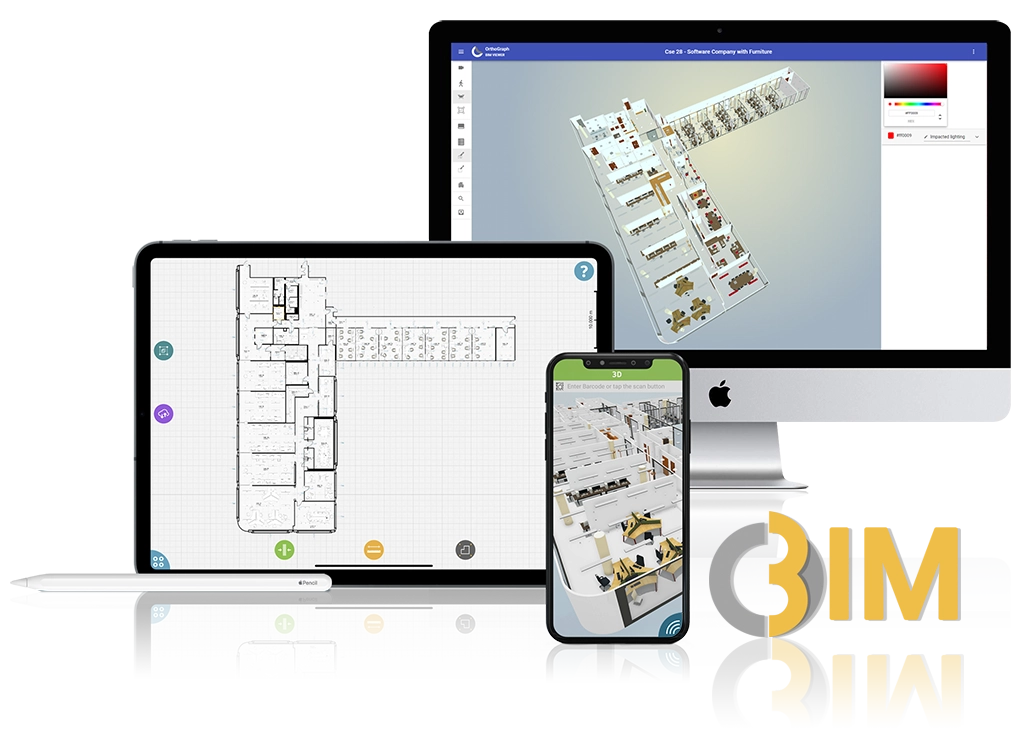

- Operational BIM is updated onsite by technicians at the time and place changes occur.

- The continuously updated digital model enables building a ‘Single Source of Truth’ (SSOT).

- This database provides reliable data for any external system requiring building or equipment information, graphical representation, or visualization.

- Maintenance history and precise equipment locations together enable technicians with appropriate qualifications to perform maintenance with the same quality and speed as equipment specialists.

- Important: After completing tasks, all changes must be recorded, updating Operational BIM with photos if necessary, ensuring long-term reliability and accuracy.

3. Slow Reaction to Critical Failures

Problem: Only the colleague familiar with the specific equipment can assist.

Solution:

- AI immediately responds to technicians’ questions and, if needed, generates maintenance plans based on equipment documentation, history, and other parameters.

- Technicians immediately see equipment locations within the Operational BIM model, enabling rapid and precise onsite navigation—even in an unfamiliar facility.

- Photos, descriptions, and other documentation linked to equipment help determine necessary materials and tools, thus:

- avoiding extra trips between the site and warehouse,

- shortening total repair time while increasing efficiency.

4. Slow Planning Process for New Production Lines

Problem: The current state assessment is missing, delaying production planning or tendering.

Solution:

- Data can be exported in CAD format for redesign, allowing engineers to work immediately on new layouts.

- Data is also available in Excel format, facilitating quick, transparent analysis, cost estimation, and tendering.

- Consequently, new production lines or capacities can be launched significantly faster, providing market advantages, especially in tenders or securing new orders.

5. Non-Optimized Space Utilization

Problem: Many manufacturing plants are unsure if new production lines can fit within existing spaces or require new buildings, leading to unnecessary and costly investments.

Solution:

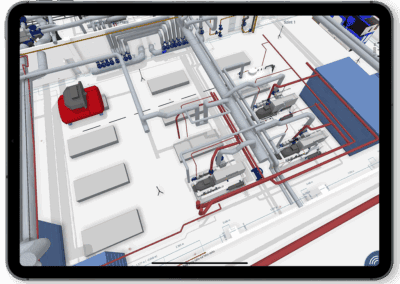

- digital reconfiguration of existing production lines, equipment, or even partitions with just a few moves,

- quickly assessing if new production lines can fit within the existing space.

- This avoids unnecessary construction of new buildings or halls,

- enabling quicker start-up of new production.

- This significantly enhances competitiveness, especially in tenders where quicker production start-up is critical.

6. Secure and Controlled Maintenance at Every Location

Problem: Scheduled preventative maintenance is skipped or performed on incorrect machines, resulting in warranty voids and unplanned stoppages.

Solution:

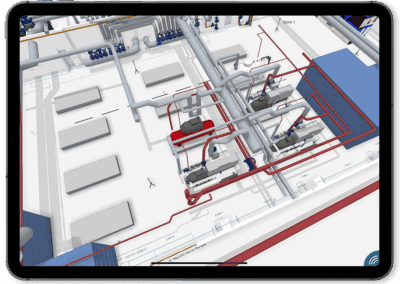

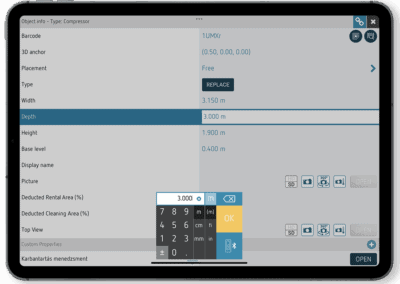

OrthoGraph’s integrated 3D digital twin acts as a functional model for maintenance:

- Maintenance points can be visualized and selected via mobile or browser in both 2D and 3D views.

- One-click access to maintenance history, future planned tasks, related documents and photos, and direct queries to the AI assistant.

- Device selection is fast and visual, eliminating guesswork.

- Upon QR-code or RFID identification, the system verifies correct equipment intervention, recording time and duration.

Why Choose OrthoGraph AI Maintenance?

- It does more than document—it thinks, providing genuine AI-based advisory support.

- Creates knowledge centers tied to maintenance points, not individuals.

- Integrates with existing systems (e.g., Maximo, Planon) or works standalone.

- Fast deployment, minimal training required, with tangible results within days.

OrthoGraph AI Maintenance is the new standard in professional technical maintenance. Build a stable, well-documented, intelligent maintenance system—before downtime forces you to.

to our Newsletter

OrthoGraph

Contact us

Contact us

OrthoGraph GmbH

Gartenstrasse 7

Zug

Switzerland

6300

+ 41 (41) 5510150

9:00-18:00 Zurich Time

USA: +1 760 933 1550

UK : + 44 (20) 34119438

Other pages

Education

Rapid Survey Concept

Orthograph for Constructions

Historical Building Survey