OrthoGraph© AI Maintenance

Maintenance Management System Documentation

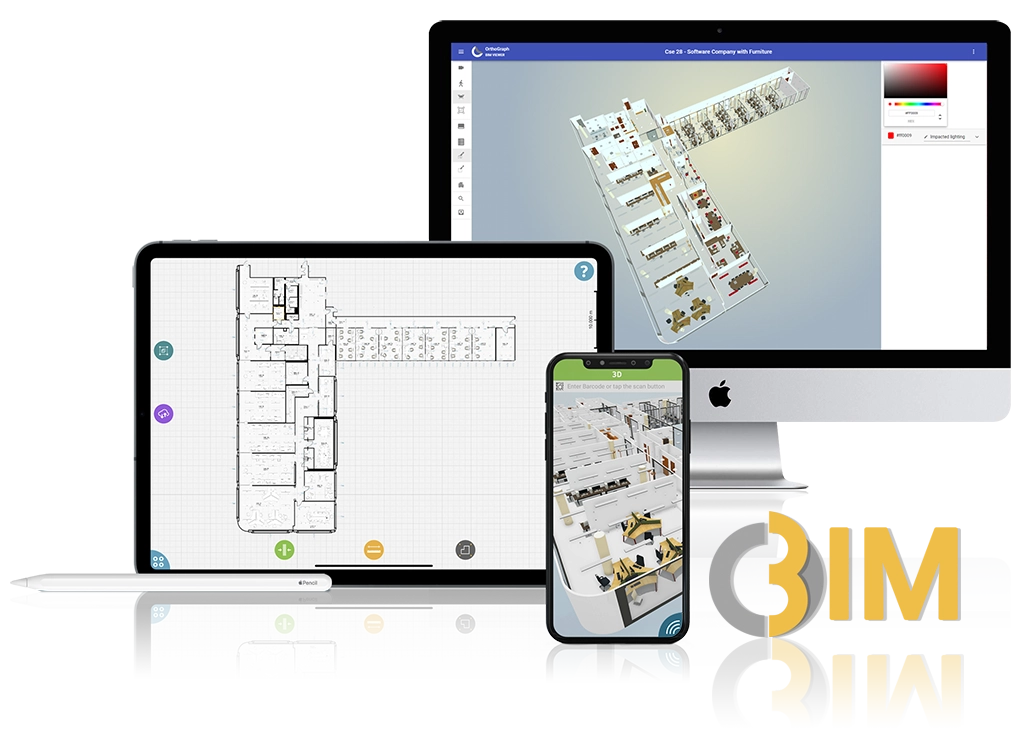

OrthoGraph’s new, fully AI-based product enables comprehensive maintenance management through deep integration with the OrthoGraph Operational BIM system. The system is quick to implement, easily scalable, and generates real value through efficient maintenance processes. Importantly, this is not an AI-enhanced extension of an existing maintenance management system or concept. It is a solution built entirely from the ground up based on artificial intelligence, OrthoGraph’s Operational BIM, and today’s mature mobile technology.

Key Features and Value Propositions

1. Interactive AI Assistance

- Enables interactive handling of documentation linked to maintenance points and equipment groups.

- Supports real-time conversation and querying, automatically interpreting the complete documentation, maintenance history, and plans related to equipment.

- Minimizes the need for training by gathering all asset knowledge and documentation in the Operational BIM system.

- Centralizes all knowledge (e.g., documents, maintenance events, tickets) related to each maintenance point and event, allowing for automatic reuse during future maintenance work or planning.

2. Controlled Fault Management Processes

- Simple, fast issue reporting directly from a web browser—no software installation required.

- Quick feedback possible using a “thumbs up” icon on existing tickets.

- AI-powered advisory support in uncertain situations.

- Detailed ticket management: short and long descriptions, photo attachments.

- When QR codes are present on equipment or rooms, issue reporting can be initiated by simply scanning the code.

- During issue handling, resource planning is supported by displaying the current workload of each resource, helping to plan rapid and efficient interventions.

- Fault handling is also available for assets or rooms without QR codes—maintenance information and AI assistance can be accessed via the central dispatcher interface.

3. Direct Issue Reporting via QR Codes

- Report issues related to equipment or rooms using mobile devices and QR codes.

- Gradual rollout possible—QR codes or 3D models are not required from the start. These can be added later, and the system automatically links related data.

- Maintenance and issue-reporting functions are accessible from any modern web browser without prior software installation, ensuring fast and platform-independent access.

4. AI-Supported Maintenance Planning

- Create interactive maintenance plans with AI assistance.

- Flexible, iterative planning process with automatic plan generation.

- AI considers machine documentation, maintenance history, existing and planned events, available staff and subcontractors, and their qualifications.

5. Controlled Workflows

- Status change tracking via QR codes or other identification technologies (e.g., RFID)—e.g., job start and completion.

- Ensures on-site verification, increasing SLA reliability.

- Supports evaluation of technician/subcontractor training and task complexity.

- Customizable status engine allows companies to tailor workflows to their practices.

- Integration with external systems for data exchange is possible, though it requires custom development.

6. Integrated 3D Support

- Maintenance processes are integrated with the Operational BIM model.

- Interactive selection of maintenance points from 2D/3D views.

- Direct access to documentation and maintenance history via mobile device or web browser.

7. Navigation Support

- On-site work is supported via mobile technology.

- Technicians receive detailed equipment information before arriving onsite, including required materials and tools—eliminating warehouse return trips and ensuring proper preparation.

- 3D-based navigation and detailed pre-job information are available during ticket handling.

- Facilitates identification of assets/rooms and accelerates communication and work execution.

8. Unified Ticket and Maintenance Management

- Single interface for managing tickets, planned maintenance, and IoT-based issue detection.

- Unique AI-based ticket generation from IoT data.

9. Fast Implementation & Organic Growth

- Use can begin immediately, with potential for organic expansion.

- Gradual implementation and integration of documentation and QR codes—even during system use.

- Progressive integration of 3D digital twins to support controlled maintenance processes, with automatic linking between system elements and digital twin models via QR codes.

- Available in both SaaS (cloud-based) and on-premise deployment options, aligning with users’ security and operational requirements.

- Flexible licensing: fees are based on system usage (number of maintenance events handled), not the number of users—bundled in scalable packages.

10. Graphical Analytics

- Data-driven color coding on floor plans and 3D models.

- CSV export for easy review and further analysis.

Summary

The new OrthoGraph AI Maintenance Management System provides a comprehensive, flexible, and intelligent solution for optimizing maintenance processes—significantly improving efficiency, accuracy, and resource utilization.

to our Newsletter

OrthoGraph

Contact us

Contact us

OrthoGraph GmbH

Gartenstrasse 7

Zug

Switzerland

6300

+ 41 (41) 5510150

9:00-18:00 Zurich Time

USA: +1 760 933 1550

UK : + 44 (20) 34119438

Other pages

Education

Rapid Survey Concept

Orthograph for Constructions

Historical Building Survey