Want to know more?

There is even more in this story, so please book a live 1:1 meeting ► with the founder and CTO of OrthoGraph, Adam Korbuly:

You can also reach Adam at akorbuly@orthograph.com

or at the mobile number of +49 176 766 19 319

or on LinkedIn:

Your Maintenance Just Got Smarter. With AI, 3D, and Real-Time Data.

Welcome to OrthoGraph AI Maintenance – the future of CMMS.

Unplanned downtimes cost hundreds of thousands of euros per hour

- Maintenance teams work blindfolded.

- Knowledge disappears with staff turnover.

- Traditional CMMS is static, slow, and disconnected from the real world.

Your plant is producing 24/7. Your maintenance system should too.

OrthoGraph AI Maintenance

AI-driven planning & diagnostics

Maintenance powered by data and smart suggestions by AI, not guesswork.

Smart breakdown reporting via QR

Report issues incl. photos on the spot with a single scan – no app or login required.

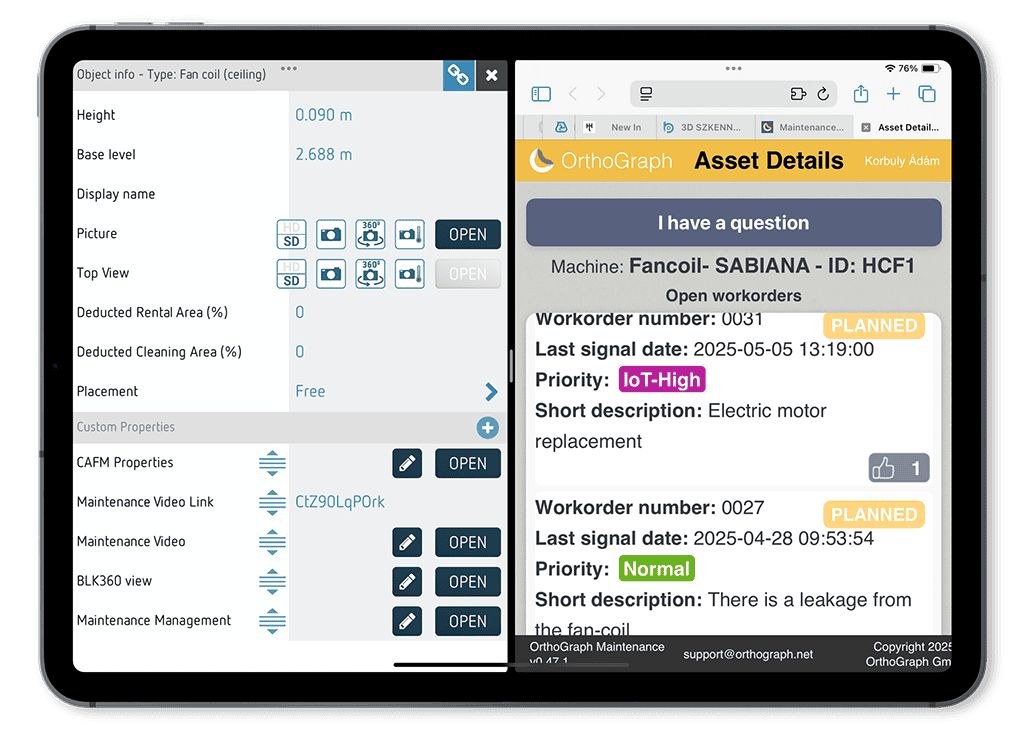

Asset-specific AI agents (talk to machines!)

Each machine has its own AI that knows its history, documents and next steps.

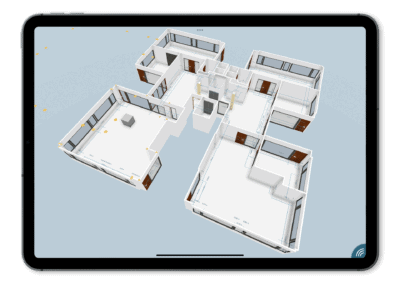

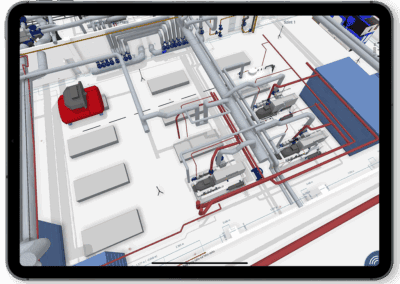

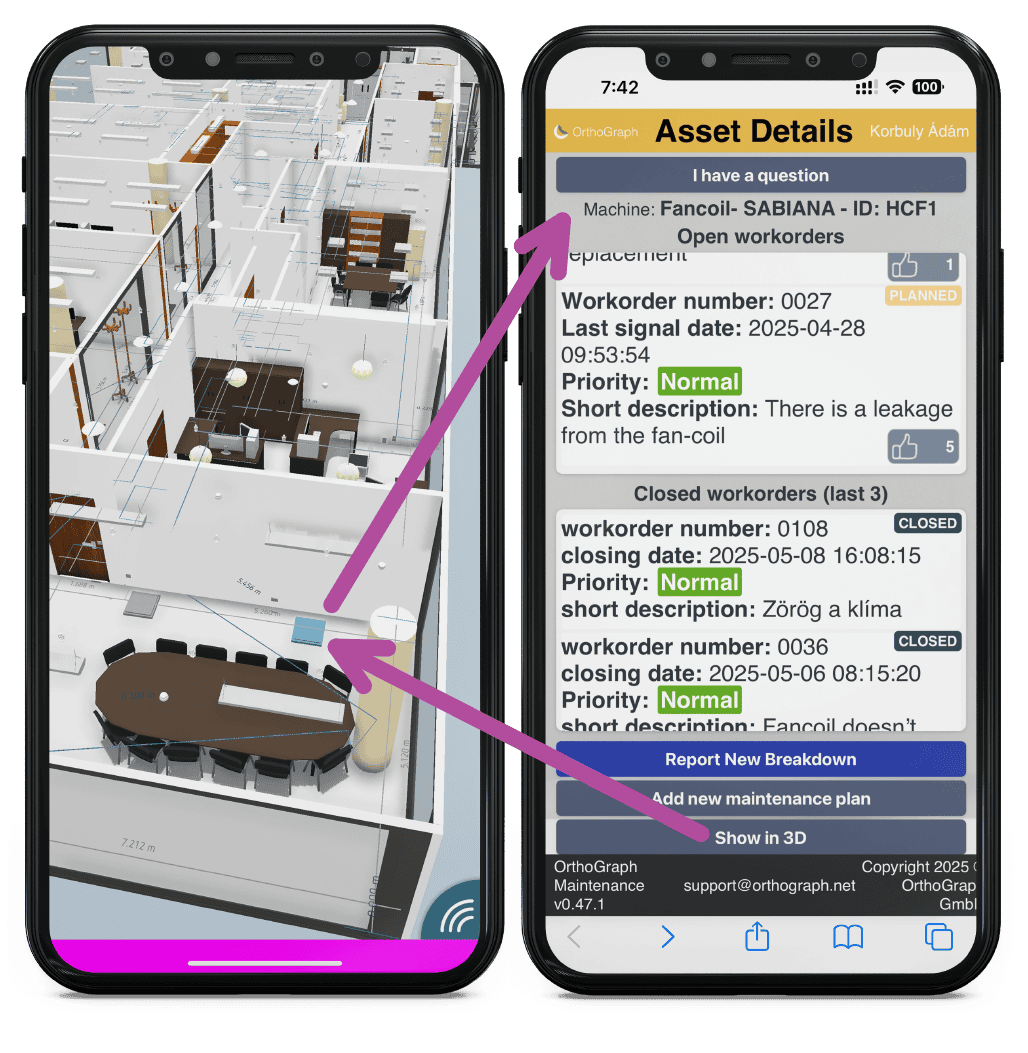

Integrated 3D navigation & documentation

Locate assets in seconds and access all visuals, documents and data right on site.

Technician-ready interface – mobile-optimized

Designed for the field: fast, intuitive and available on any smartphone or tablet.

Workflow

- Breakdown → QR-scan or dispatcher call → Smart form or speech input (assisted by the mobile)

- AI assists task generation / maintenance plan creation

- Technician navigates via 3D model

- Feedback documented instantly

- AI learns & improves

Data-Driven Maintenance Starts with the Right Data

- Up-to-date asset inventory

- 3D Digital Twin, editable on-site

- QR/RFID/NFC unique IDs

- Photos, panoramas, thermal images, metadata

- Maintained by your own team

A Maintenance Ecosystem That Plays Well with Others

- OrthoGraph = Single Source of Truth

- Real-time updates from field to office

- Free and open API – integrates with:

- ERP, BMS, SCADA, MES, IWMS, CAFM

- Accessible on any device

- Embeddable 2D/3D viewer

Real Results in Real Factories

- Several hours of downtime (multiple hundreds of thousands of dollars) saved each time the trouble occurs

- 10-20% maintenance cost reduction

- 100% traceability in audits

- 95% less planning time

- Clients: food, pharma, electronics, automotive, energy – any type of production facilities

ROI

- 5x ROI in year one

- Up to 40x ROI in long-term use

- No post-processing cost

- No external CAD/BIM team needed

Try OrthoGraph in a pilot project – and see the difference in days.

Provide us with a few quick details:

- How large is the area you want to try it in?

- How many maintenance points would you like to involve?

- How many maintenance requests do you expect per year?

We’ll get back to you with a tailored pilot proposal.

Want to know more? Let’s talk!

There is even more in this story, so please book a live 1:1 meeting ► with the founder and CTO of OrthoGraph, Adam Korbuly:

You can also reach Adam at akorbuly@orthograph.com or at the mobile number of +49 176 766 19 319 or on LinkedIn: https://www.linkedin.com/in/korbuly/

to our Newsletter

OrthoGraph

Contact us

Contact us

OrthoGraph GmbH

Gartenstrasse 7

Zug

Switzerland

6300

+ 41 (41) 5510150

9:00-18:00 Zurich Time

USA: +1 760 933 1550

UK : + 44 (20) 34119438

Other pages

Education

Rapid Survey Concept

Orthograph for Constructions

Historical Building Survey