Comparison Table:

OG AIMNT vs. General Maintenance System

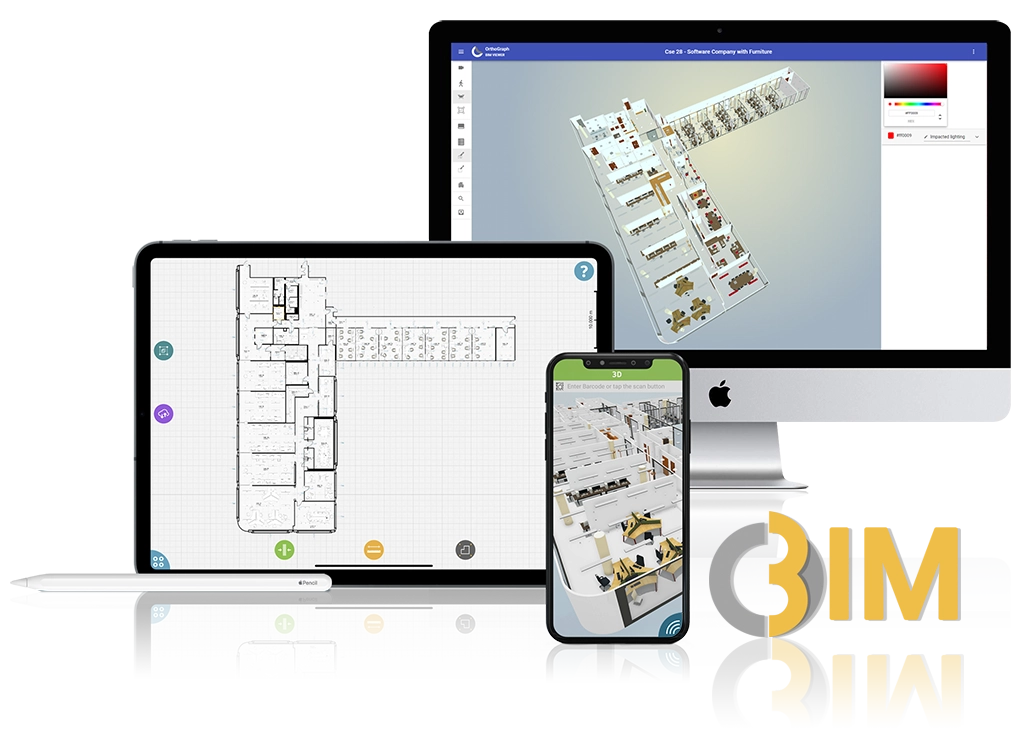

Traditional maintenance management systems have evolved over decades, adding layer upon layer of functionality to support users in their everyday operational challenges. However, many of these systems have become overly complex, difficult to learn, and ill-suited for the pace of today’s technology. With the advent of artificial intelligence and Operational BIM, a new era has begun. That’s why OrthoGraph reimagined maintenance from the ground up: AIMNT was designed to deliver exactly what is needed – nothing more, nothing less – with speed, simplicity, and outstanding efficiency.

The table below compares OrthoGraph AI Maintenance (AIMNT) with conventional maintenance systems, highlighting the key differences that bring measurable advantages to daily operations.

| Feature / Capability | OrthoGraph AI Maintenance (AIMNT) | General Maintenance System |

|---|---|---|

| Implementation time | Deployed in weeks (works without OBIM too) | Months, requires complex customization and integration |

| Learning curve | Exceptionally quick and intuitive due to AI and natural language control | Days/weeks, every new employee starts from scratch |

| AI assistant support | Natural language interaction in reporting, analysis, and planning phases | Absent or very limited AI capabilities |

| “Talk with the equipment” | Every equipment “understands” its linked documentation, maintenance history, and provides answers via AI based on all available info | Absent or minimal AI capabilities |

| (Natural language interaction) | Deeply integrated with the always up-to-date Operational BIM (OBIM), automatic access to 3D location and equipment data, detailed asset inventory, unique asset IDs, and workflow linking | Typically no integrated digital twin, or integrated asset inventory |

| Digital twin integration | Digital Twin available on mobile devices, all model elements and equipment can be accessed via their specific deep link, enabling instant positioning | Even if there is an integrated 3D BIM available, it becomes obsolete, making navigation ineffective |

| On-site navigation | Full maintenance and fault history instantly available | Typically requires manual search or queries |

| Access to historical data | Role-based detailed access control | Generally limited or basic access control |

| User access levels | Tracks materials, tools, wear, and contract-level document movement with QR code support | Optional module or not available |

| Spare parts & warehouse tracking | Immediate ticket creation by scanning QR code | Manual data or menu-based entry |

| Initiation method | Unique equipment or room ID (QR/RFID) is mandatory to check at job start/finish | Unique ID setup is challenging and costly, so it is rarely implemented |

| Maintenance plan creation | Built-in AI-supported load and skill-based planning for staff and subcontractors | Partially available, usually handled in external systems |

| Resource & competency planning | Real-time 3D model and equipment position | Not commonly available |

| 3D and location data access | AI-assisted conversational reporting, exportable to Excel | Static template-based, often manually compiled |

| Reporting | Direct access to documents linked to equipment | Stored in separate file systems or modules |

| Document management | Integrated cost planning for maintenance | Financial planning handled externally |

| Financial planning | The same data is accessible to all users via AI and OBIM | Performance drops without staff’s familiarity with the facility |

| Efficiency without local knowledge | Simple: transparent packages based on expected ticket volume | Complex: licensing and pricing vary per module |

to our Newsletter

OrthoGraph

Contact us

Contact us

OrthoGraph GmbH

Gartenstrasse 7

Zug

Switzerland

6300

+ 41 (41) 5510150

9:00-18:00 Zurich Time

USA: +1 760 933 1550

UK : + 44 (20) 34119438

Other pages

Education

Rapid Survey Concept

Orthograph for Constructions

Historical Building Survey